Thermal analysis plays a crucial role in various industries, ranging from electronics and automotive design to building construction. By employing a comprehensive thermal analysis service, you can gain valuable insights into your project that can result in improved performance, reduced costs, and enhanced product quality. In this article, we will explore the significance of thermal analysis and how it can benefit your project.

What is Thermal Analysis?

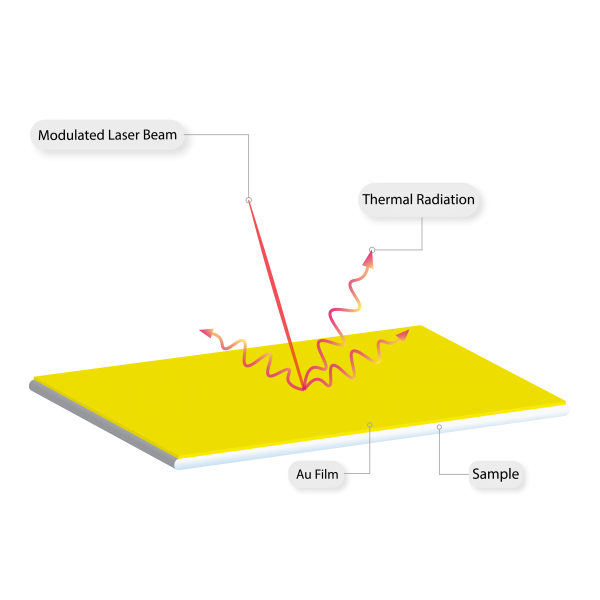

Thermal analysis is a scientific method used to study the behavior of materials under different temperature conditions. It involves measuring and analyzing various thermal properties, such as heat capacity, thermal conductivity, and coefficient of thermal expansion. By simulating real-world thermal conditions, engineers and scientists can better understand how materials and systems respond to heat and make informed decisions regarding design optimizations.

What is the importance of thermal analysis in projects?

Thermal analysis is crucial in projects where temperature regulation and management are critical. Whether it’s designing electronic components, optimizing cooling systems, or constructing energy-efficient buildings, understanding the thermal behavior of materials and systems is essential. By gaining insights into heat transfer, thermal stress, and energy consumption, project stakeholders can make informed decisions and improve overall project outcomes.

What essential information can a comprehensive thermal analysis service unearth for your project?

A comprehensive service can provide several valuable insights into your project. Let’s explore some of these insights:

Insight #1: Identifying Heat Transfer Issues

Thermal analysis helps in identifying potential heat transfer issues within a system. By modeling and simulating heat flows, engineers can identify areas of high thermal resistance, heat concentration, or inadequate cooling. This insight allows for targeted design modifications to improve heat dissipation, prevent overheating, and enhance system performance.

Insight #2: Optimizing Cooling Systems

For projects that rely on effective cooling systems, the thermal analysis offers valuable insights into system optimization. By simulating cooling mechanisms, such as airflow, heat sinks, or liquid cooling, engineers can evaluate their effectiveness and identify potential areas for improvement. This insight enables the design of efficient cooling systems that ensure optimal performance and prevent component failures due to overheating.

Insight #3: Enhancing Product Performance

Thermal analysis can uncover opportunities to enhance product performance by optimizing thermal management. By evaluating the effects of temperature on materials, engineers can identify design modifications to improve product efficiency, reliability, and durability. This insight is particularly valuable in industries where performance under various temperature conditions is critical, such as automotive, aerospace, and electronics.

Insight #4: Avoiding Component Failure

Thermal analysis services help in identifying potential issues that can lead to component failure. By analyzing thermal stress, temperature gradients, and material properties, engineers can assess the reliability and durability of components under different operating conditions. This insight allows for design improvements that mitigate the risk of premature failure and increase the lifespan of critical components.

Insight #5: Minimizing Energy Consumption

In projects that aim for energy efficiency, it can provide insights into minimizing energy consumption. By evaluating heat losses, thermal insulation, and energy transfer, engineers can identify areas for improvement to reduce energy waste. This insight not only contributes to cost savings but also aligns with sustainable design practices and environmental considerations.

What is the process of thermal analysis?

Thermal analysis typically involves the following steps:

Step 1: Gathering Project Details

The first step in thermal analysis is to gather project-specific details, such as dimensions, material properties, and operating conditions. This information forms the basis for building an accurate thermal model.

Step 2: Building the Model

Using specialized software, engineers create a 3D model that represents the project system. The model includes components, materials, and boundaries to simulate real-world conditions accurately.

Step 3: Applying Boundary Conditions

Boundary conditions, such as temperature, heat sources, and cooling mechanisms, are applied to the model. These conditions mimic the actual operating environment and allow for accurate simulations.

Step 4: Running Simulations

Once the model and boundary conditions are set, engineers run simulations to analyze heat transfer, thermal stress, and other relevant parameters. Advanced numerical methods solve the equations governing heat transfer and provide detailed insights into the system’s behavior.

Step 5: Analyzing Results

The final step involves analyzing the simulation results. Engineers interpret the data to understand heat flow patterns, temperature distributions, and areas of concern. This analysis forms the basis for making informed decisions and implementing design optimizations.

How to choose the right thermal analysis service provider?

When selecting a service provider, consider the following factors:

- Expertise and Experience

Look for a provider with a team of experts who have extensive experience in thermal analysis. They should have a deep understanding of various industries and the challenges associated with thermal management.

- Range of Services Offered

Choose a provider that offers a comprehensive range of it. This ensures that they can meet your specific project requirements and provide insights tailored to your industry.

- Technical Capabilities and Software

Ensure that the provider utilizes state-of-the-art software and tools for thermal analysis. Advanced simulation capabilities enable accurate and detailed insights into thermal behavior.

- Timeliness and Cost-Effectiveness

Select a provider that delivers results within the desired timeframe and offers cost-effective solutions. Prompt delivery of analysis results is crucial for project timelines and decision-making processes.

Conclusion

In conclusion, a comprehensive thermal analysis service can uncover valuable insights for your project. By understanding heat transfer, optimizing cooling systems, enhancing product performance, avoiding component failures, and minimizing energy consumption, you can achieve improved project outcomes and cost savings. When choosing a service provider, consider their expertise, range of services, technical capabilities, and timeliness. By harnessing the power of thermal analysis, you can make well-informed decisions and secure the success of your project.

Thanks for visiting postmyblogs