Modern 2D and 3D drafting technologies transform furniture shop drawings, providing precision documentation, enhanced visualization, and direct manufacturing integration. These tools enable accurate component design, efficient production workflows, and improved quality in finished furniture pieces.

Creating precise documentation is crucial for furniture manufacturing as inaccurate measurements lead to material waste, production delays, and quality issues. Manual drafting processes consume excessive time and resources. They often create communication gaps between designers and fabricators that result in costly errors.

2D and 3D drafting techniques for furniture provide comprehensive solutions to these problems. Implementing advanced CAD furniture drawings helps you gain access to precise dimensional control, improve visualization capabilities, and streamline manufacturing processes.

Here we discuss how modern drafting approaches transform the creation of furniture shop drawings, enhancing accuracy, reducing errors, and optimizing production workflows in professional furniture design and manufacturing.

What are furniture shop drawings?

Furniture shop drawings are detailed technical documents that specify the exact construction requirements for furniture pieces. These documents serve as the communication bridge between designers and fabricators, ensuring all parties understand the exact specifications.

For example, furniture layout drawings provide spatial arrangement details showing how components relate to each other within the overall piece. Joinery shop drawings highlight critical connection points requiring precision manufacturing to ensure structural integrity.

Shop drawings for furniture typically include:

- Dimensioned plans: Complete measurements of all components with specified tolerances, scale ratios, and dimensional hierarchies for primary/secondary features.

- Material specifications: Detailed listings of required materials with grades (e.g., FAS hardwoods, C/D plywood), finishes (20° sheen lacquer, oil-rubbed), and grain direction notations.

- Construction details: Precise representations of joinery methods (mortise depths, tenon dimensions), assembly sequences, and load-bearing structural requirements.

- Hardware specifications: Comprehensive documentation of required hardware components including fastener types, specific manufacturers, part numbers, and installation torque requirements.

The role of 2D drafting in furniture production

2D furniture drafting represents the foundation of technical documentation in furniture manufacturing. This approach uses orthographic projections to display furniture from different viewpoints, creating precise representations of components and assemblies.

Fundamental 2D drawing types

2D furniture drafting typically include several standard orthographic projections:

- Plan views: Top-down representations showing overall dimensions, component layouts, and spatial arrangements essential for furniture layout drawings.

- Elevations: Front, side, and rear projections displaying vertical dimensions, profiles, and other details.

- Sections: Strategic cut-through views revealing internal construction methods, joinery connections, and assembly requirements.

- Details: Enlarged drawings of complex joinery connections, hardware installation specifications, material transitions, and specialized components at critical scales (1:2, 1:1).

Technical drawings for furniture created in 2D environments provide clear dimensional data essential for manufacturing processes. You can generate precise cutting lists, determine material requirements, and plan fabrication sequences directly from these drawings.

Advantages of 2D drafting for furniture shop drawings

The implementation of 2D furniture drafting delivers several key benefits:

- Dimensional precision: Exact measurements with controlled tolerances reduce material waste and rework while ensuring component interfaces align correctly.

- Manufacturing focus: Clear fabrication instructions with specific tool paths, machining sequences, and assembly protocols minimize production errors.

- Efficient communication: Standardized documentation with drafting conventions facilitates smooth information transfer between design teams and production departments.

- Resource optimization: Accurate material quantities with predetermined cutting layouts improve cost estimation and inventory management.

- Quality control: Established dimensional benchmarks provide verification points for inspection processes throughout manufacturing stages.

3D drafting: Advanced furniture design visualization

3D furniture drafting extends documentation capabilities beyond traditional 2D representations. Custom furniture drawings particularly benefit from 3D modeling capabilities, enabling visualization of client-specific requirements and unique design elements.

Key components of 3D modeling

Modern 3D CAD furniture design incorporates the following critical elements:

- Parametric modeling: Component relationships maintain dimensional integrity during modifications, with constraints that preserve design intent across multiple iterations

- Assembly simulation: Complete furniture pieces assembled virtually to verify fit and function, including analysis for moving parts like drawers and doors.

- Material rendering: Realistic material representations with physically accurate properties (reflectivity, texture, translucency) to evaluate aesthetic characteristics under various lighting conditions.

- Interference detection: Automated collision identification preventing assembly issues through geometric boundary analysis and clearance verification for hardware operation.

Furniture design drawings created using 3D CAD modeling thus help furniture manufacturers by providing comprehensive visualization capabilities and efficient communication of design intent.

Manufacturing integration capabilities

Advanced 3D furniture drafting directly connects to manufacturing processes through the following:

- CNC programming: Direct generation of G-code and tool path instructions for multi-axis CNC fabrication with optimized feed rates and tool selection parameters for CNC furniture drawings.

- Material optimization: Algorithmic nesting protocols achieving material utilization efficiency through computational geometry analysis of cutting patterns.

- Assembly sequencing: Virtual build visualizations employing precedence constraints and critical path analysis to determine optimal production workflows.

- Quality verification: Dimensional comparison between manufactured components and design specifications through CMM integration with deviation tolerance.

- Post-processing planning: Automated calculation of secondary operations like edge banding, veneer application, and finishing requirements with thickness compensation parameters.

Comparing 2D and 3D drafting approaches for furniture shop drawings

Understanding the differences between 2D and 3D furniture drafting helps determine the optimal approach for specific projects. The following table gives a comparison of the two approaches of creating furniture shop drawings:

| Feature | 2D Drafting | 3D Drafting |

| Dimensional representation | Flat orthographic views | Volumetric models with full geometry |

| Visualization capability | Limited to trained technical readers | Accessible to all stakeholders |

| Design modification process | Requires updates to multiple views | Parametric changes propagate automatically |

| Manufacturing integration | Instructions created through interpretation | Direct machine instruction generation |

| Hardware verification | Manual interference checking | Automated collision detection |

| Documentation generation | Extraction from drawings | Automated from 3D model |

Both approaches deliver specific benefits, with many professional furniture drafting services implementing hybrid workflows that leverage the strengths of each method.

Leveraging CAD software for furniture shop drawings

The selection of appropriate furniture drafting software impacts documentation capabilities and production efficiency. Selection criteria should prioritize parametric modeling capabilities, furniture-specific libraries, and manufacturing integration protocols that align with production equipment specifications.

Industry-standard furniture drafting CAD tools

Three specialized applications – AutoCAD, SolidWorks and Inventor, are used majorly in professional furniture shop drawings creation:

AutoCAD

AutoCAD furniture drawings leverage specialized functionality essential for furniture shop drawings.

Here are some of the features:

- Dynamic blocks: Create parametric furniture components with adjustable dimensions that maintain proportional relationships.

- Layer management: Separate drawing elements into dedicated layers for dimensions, materials, hardware, and annotations.

- Xrefcapabilities: Reference standard furniture components across multiple drawings while maintaining update capabilities.

- Sheet sets: Organize multiple furniture design drawings into cohesive documentation packages with automated title blocks.

- Dimensioning tools: Apply furniture-specific dimension standards with automatic tolerance calculations.

SolidWorks

For comprehensive 3D furniture drafting, SolidWorks offers the following major specialized capabilities:

- Feature-based modeling: Build furniture components using operations that mirror actual manufacturing processes.

- Assembly constraints: Define precise relationships between furniture parts to simulate actual assembly conditions.

- Configurations: Create multiple variations of furniture pieces within a single file for product line development.

- Sheet metal tools: Design metal furniture components with automatic flat pattern development for fabrication.

- Weldment features: Model welded furniture frames with proper joint preparation and structural analysis.

- Exploded views: Generate assembly documentation showing component relationships for manufacturing instructions.

Inventor

Autodesk Inventor combines specialized 2D and 3D drafting tools for furniture drafting. Following are some of the major features it offers:

- Frame generator: Design and document furniture frames using standardized structural profiles.

- iLogic API: Develop programmatic rule-based furniture configurators with conditional design parametersthat adjust automatically based on parameter changes.

- Drawing automation: Generate complete technical drawings and CAD furniture plans directly from 3D models with automatic dimensioning.

- CNC integration: Export manufacturing data directly to CNC machinery for precise furniture component fabrication.

Precision improvements through digital drafting

Both 2D and 3D drafting approaches significantly enhance accuracy in furniture shop drawings compared to traditional manual methods. Digital environments implement dimensional constraints that maintain geometric relationships during modifications while providing automated mathematical verification of measurements.

Version control systems prevent manufacturing from outdated specifications through comprehensive documentation tracking. Standardized representation methods in technical drawings for furniture ensure consistent interpretation across departments.

These technologies effectively reduce measurement errors, improve component fit during assembly processes, and enhance overall quality in wood furniture design drawings, delivering superior finished products.

Case Study

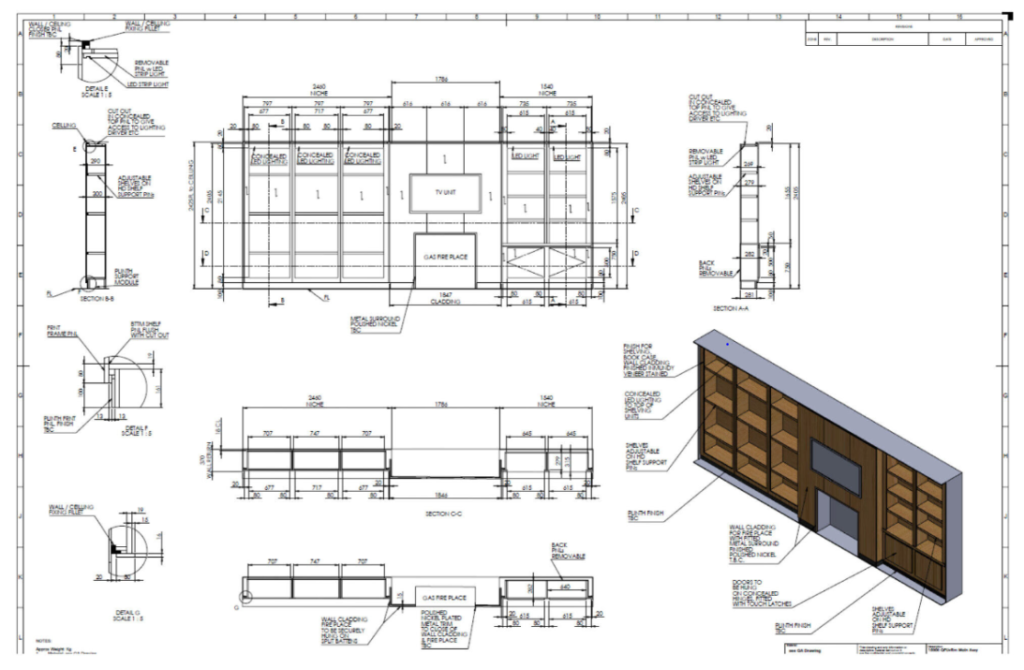

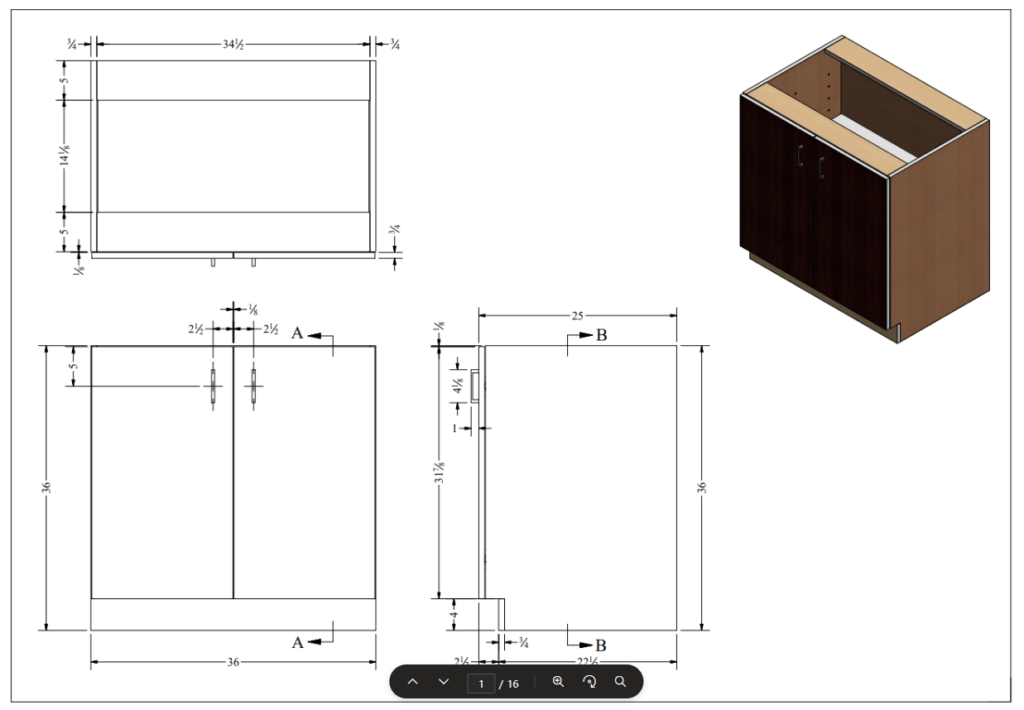

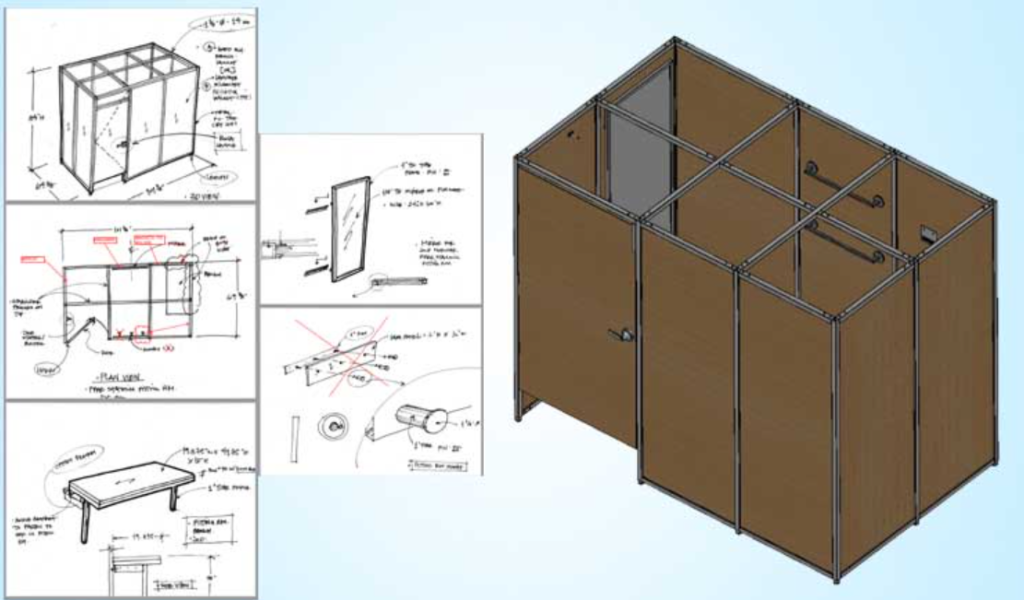

CAD Detailed Drawings and 3D Models for Retail Furniture Manufacturer

A UK-based retail furniture designer and manufacturer sought to transform their hand-drawn concept sketches into precise manufacturing drawings. The client required detailed 2D CAD drawings and 3D models to streamline their production process and ensure accuracy in manufacturing.

TrueCADD collaborated with the client to convert their conceptual sketches into comprehensive CAD models. The team developed 3D models and manufacturing drawings for retail furniture components, including fitting rooms, ensuring all designs adhered to the client’s specifications and industry standards.

The final deliverables led to the following:

- Enhanced design accuracy

- Streamlined production processes

- Improved communication

Optimizing 2D and 3D drafting workflows for furniture production

Maximizing the benefits of 2D and 3D drafting for furniture shop drawings requires strategic implementation approaches:

- Develop furniture-specific templates: Create standardized drawing formats with predetermined sheet sizes, title blocks, and annotation styles specifically calibrated for furniture documentation requirements including joinery details and hardware specifications.

- Establish component libraries: Build comprehensive collections of standardized hardware, joinery methods, material specifications, and common furniture elements to accelerate drawing creation and maintain consistency across product lines.

- Implement drawing revision control: Maintain detailed version histories with change documentation to track design evolution, prevent manufacturing from outdated specifications, and create transparent modification audit trails.

- Create material-specific standards: Develop documentation standards for different furniture materials including wood, metal, upholstery, and composites with appropriate dimensioning conventions and fabrication notations.

- Implement drawing approval protocols: Establish formal review processes with specific verification checkpoints for dimensions, materials, hardware specifications, and manufacturing feasibility before releasing furniture manufacturing drawings.

- Develop integration standards: Create standardized methods for exchanging drawing data between drafting environments and manufacturing systems including CNC machinery, inventory management, and production scheduling

Following these practices enhances the effectiveness of both 2D and 3D drafting approaches for furniture shop drawings, improving documentation consistency and communication throughout the design and manufacturing process.

Conclusion

2D and 3D drafting technologies transform the creation of furniture shop drawings, delivering substantial improvements in documentation accuracy, visualization capabilities, and manufacturing integration. By implementing these advanced approaches, you gain precise dimensional control, enhanced stakeholder communication, and streamlined production workflows.

The selection between 2D furniture drafting and 3D furniture drafting, or hybrid approaches depends on specific project requirements. As manufacturing technologies continue advancing, the integration between digital drafting and automated production systems becomes increasingly seamless. Implementing these technologies positions your furniture design and manufacturing operations for optimal efficiency, reduced errors, and enhanced product quality.